Polished Cement Tile Benefits

Polished Cement Tile Benefits

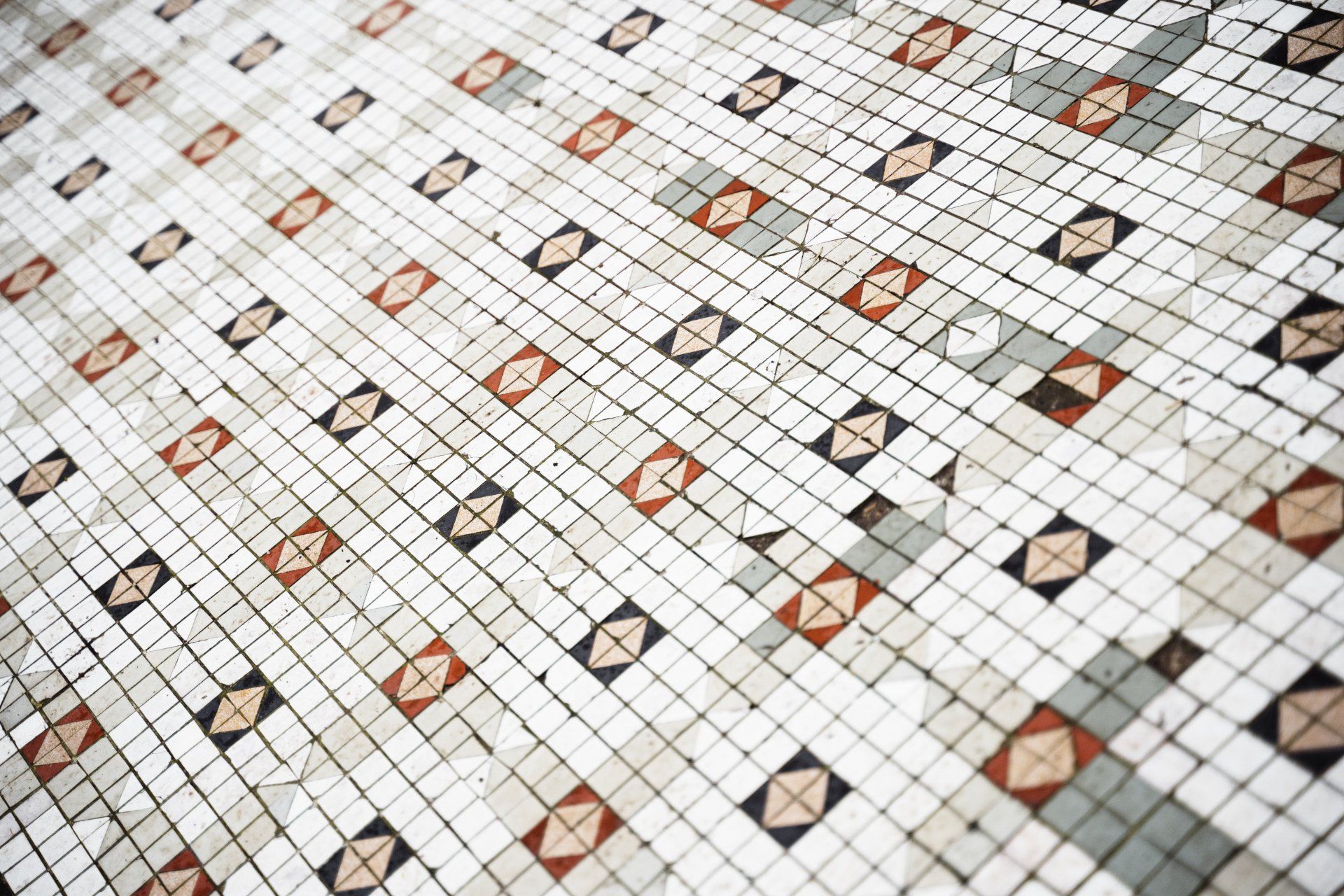

Raw, unpolished, or polished are the three terms utilized to refer to the look of cement tiles. Polishing and the look of cement tiles are widely confused when comparing the prices and slip resistance, the ability to install, and desired appearance. It's essential to know the purpose of polishing and what it does to the tile, and the reasons why it's advantageous to choose polished tiles when they are they are available.

What is Cement Tile Polishing?

If cement tiles are shipped directly from the manufacturer, customers could choose a "polished" and "unpolished" surface. Unpolished tiles are also identified as having a "raw" finish and tend to appear "chalky" when removed from the container. Most factories make raw or unpolished cement tiles. However, many suppliers give the option of getting tiles that have been polished by a factory.

Common Questions and Answers on Polished Cement Tile

Polished tiles are lustrous satin sheen that resembles the appearance that all cement floor tiles attain after a period of time and use. This sheen results from forces that abrasively impact the tile due to everyday usage. Below are some answers to the commonly asked questions regarding polishing the cement tile.

What exactly is polishing?

Polishing is a mechanical procedure that uses a high-speed rotary buffer and mild abrasives as well as water in order to "polish" each tile. This process mimics the "patina" that a tile may develop over the course of many years of cleaning it using water and wax.

Are polished tiles really glossy and slippery?

No. Polished tiles are of moderate appearance, with a flat satin finish, and aren't as rough. Polished cement tiles can be used for flooring. It is important to note that, while their coefficient of friction for polished tiles is in the range that is acceptable for slip resistance, it's different from that of an unpolished tile.

Are polished tiles likely to have longer-lasting life?

No. The tiles are not polished. It does not extend the lifespan of the tiles.

Does polished tile require greater maintenance since areas with high treads will reduce "polish" and result in "walking lanes" with time?

No. Polishing at the factory isn't like the floor's wax. The polishing process in factories does not produce a "layer of polished" over the tiles. If not maintained properly, tiles can become glossy "walking paths" in areas with high traffic. To prevent this from happening, ensure the floor is well maintained and kept clean.

What is the benefit of polishing tiles?

When installed and cured, the tiles instantly create the appearance of a "lived in" appearance with a soft satin sheen. This effect will continue as you use them for normal maintenance.

Benefits of Polished Cement Tile

Once you know the purpose of polishing and the process of doing it, we can discuss the advantages and the times when you should look into using polished cement tiles, if there is one available. As we said earlier, most factories make raw cement tiles that are not polished or polished. Tiles that are polished are slightly more costly, and you must keep this in mind when comparing costs.

Color bleed is prevalent when using high contrast tiles, for example, patterns that utilize the colors white or black. Color bleed is a result when cement tiles are placed within racks taken from a bath of water that is required to reinforce the tiles when they cure. The water sucks up tiny amounts of pigment and then drains into the tile. The darker pigments wash across the lighter parts on the tiles, creating some faint discoloration. This is a normal aspect of the manufacturing process, but it's not recommended for backsplash tiles, which are in the spotlight.

Additionally, polished tiles are typically easier to set up because grout isn't able to stick to the smoother surface. In general, the case of a grout release is not necessary when using polished tile. However, for cement tiles that are raw, we believe it's an excellent security measure.

The only instance where we would not recommend polished tiles is for outdoor patio use. Simply put, the polishing advantages are quickly lost with time due to elements like weather, wear and wind. Furthermore, if your project is time-sensitive, you might want to avoid polishing the tile because the tiles must dry before polishing. The time needed to cure is longer for polishing.